Pallet Strapping Machines

Achieve Optimal Pallet Strapping With Cyklop

Unwavering Consistency

You can rely on Cyklop pallet strapping machines to deliver tight, secure wraps every single time. Their advanced technologies ensure uniform tension is applied to each strap, eliminating gaps or loose areas that could compromise load integrity.

Perfect palletizing means your products arrive in pristine condition - no shifting, spills, or damage. With Cyklop's meticulous strapping, you can breathe easy knowing your shipments are fully contained.

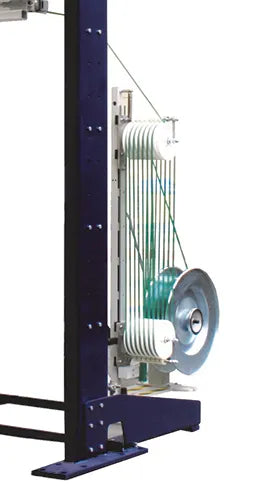

Built for Endurance

These robust machines are engineered for the most demanding industrial environments. Heavy-duty components and durable construction allow Cyklop strappers to withstand years of continuous use.

You'll appreciate their low maintenance requirements and long service life. Reliable uptime translates into stellar productivity gains for your operation.

Rapid, Effortless Operation

Intuitive controls and automated processes make Cyklop strappers remarkably simple to use. Your staff can quickly learn the equipment, keeping work flowing smoothly.

The machines rapidly secure pallets with push-button ease. This efficiency enables a fast packaging cadence to support even your highest volume needs.

Safety Prioritized

Safeguarding personnel is a prime consideration. Cyklop integrates an array of safety features to protect operators, from strap end guards to emergency stops.

The machines meet all pertinent industry safety certifications. You can run them confidently, assured your workers are shielded from potential hazards.

With rugged longevity, simple usability and precision performance, Cyklop pallet strapping machines empower you to achieve the ideal wrapped pallet, load after load. Streamline your packaging process while securing your shipments for true peace of mind.

Case Strapping vs. Pallet Strapping

Weighing the Options

When choosing between case strapping and pallet strapping, it’s essential to consider the differences in application and machinery. Each method serves distinct purposes, so understanding these can help you select the best approach for your packaging needs.

Case Strapping

Case strapping is primarily used to secure individual boxes or cartons. It offers:

- Precise, tight strapping to prevent product shifting within cases

- Ideal for light to medium-weight loads

- Suitable for packaging lines with smaller items

This method is generally faster and more straightforward, making it perfect for high-speed lines needing consistent strapping of individual units.

Pallet Strapping

Pallet strapping, on the other hand, is used to stabilize larger, heavier palletized loads. Key benefits include:

- Securement of multiple units onto a single pallet

- Ideal for heavy-duty operations

- Ensures load stability during shipping or storage

Pallet strapping machines, whether semi-automatic or fully automatic, are designed to handle the scale and