Plastic PVC Pipe Marking & Coding

PVC pipes are the veins and arteries of the modern world, bringing trillions of gallons of clean water into our homes and yards every year and then carrying away the waste. Public health and safety depend on the strength and reliability of these pipes—and on swift, effective repairs in the rare event that they fail. This makes clear and durable PVC pipe marking and coding a critical task for manufacturers.

PVC pipes require particular marks and labels to comply with safety regulations. Examples include:

- Gas content identification codes

- Fire safety color codes

- Ammonia refrigeration codes

- Country-specific identification codes

- Traceable lot codes/batch numbers

-

Production date codes

Finding the right printer and ink combination is, therefore, vital to success—and our experts here at InkJet, Inc. are happy to help you discover the ideal pair for your production line's specific needs.

Reliable Printers for PVC Pipe Marking and Coding

Production keeps going even when the going gets tough—and so should your printer. Our printers can print high-quality, high-contrast codes quickly and accurately with minimal downtime and maximum efficiency, even in harsh industrial settings.

This table lists our various PVC pipe marking and coding systems and their general specifications. Additional information for each option can be found further below in this post. Click the linked title in the table’s leftmost column to jump to a specific solution.

Continuous Inkjet Printers: DuraCode Touchscreen, Keyboard, and Pigment

Continuous inkjet (CIJ) printers are non-contact production line printing systems designed to mark substrates moving at 300 m/min and above. Built with powerful ink circulation systems, CIJ printers can operate up to 24 hours daily without downtime. The speed, wide ink compatibility, and versatile printheads of CIJ printers enable users to mark thousands of products a day with long-lasting, highly legible codes.

InkJet, Inc. meets diverse coding needs by maintaining a comprehensive CIJ ink catalog that contains dozens of formulas ideal for industrial PVC pipe coding. We have more than 30 years of experience producing ink and carry many formulas with special properties, including:

- Heat resistance

- Extreme temperature resistance

- Oil/grease penetration

- Condensation penetration

- Soft and hard pigmentation

- Superior substrate adhesion

- Ultra-quick dry times

- Anti-transfer properties

- Rub resistance

-

Alcohol resistance

No matter where your PVC pipes are used or what coding regulations you must meet, InkJet, Inc. provides the ideal printer/ink combo for your application.

|

All DuraCode systems can mark porous and non-porous substrates at speeds up to 320 m/min. Equipped with an IP55 outer structure and able to operate in temperatures ranging from 41-113° F, the DuraCode CIJ can withstand potentially hazardous environmental elements to deliver consistently excellent results.

|

|

|

See the chart below for a closer look at the DuraCode models’ most important specifications.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

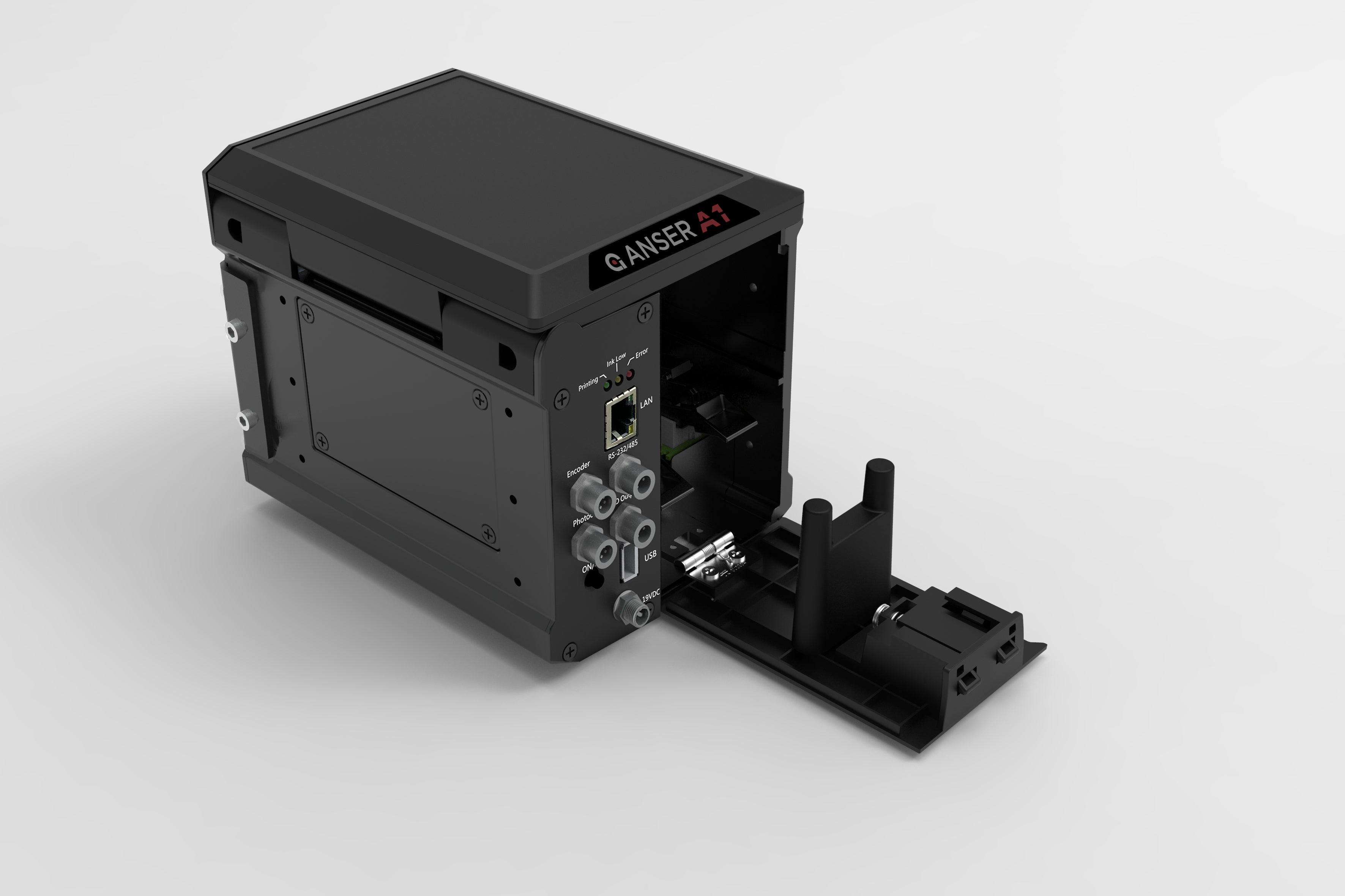

Thermal Inkjet Printers: Anser U2, X1, and A1 Models

Thermal inkjet (TIJ) printers are smaller, lighter, and more cost-effective than CIJ systems. While CIJ systems typically weigh around 100 lbs and can cost well over $10,000, most TIJ models weigh 5-10 lbs and cost as low as $1,499.00.

Although thermal inkjet systems are compact and lightweight, they offer impressive coding specifications. For example, the Anser U2 Smart can create 400 x 300 DPI codes up to 0.5” tall (1” tall with the Anser U2 SmartOne). Higher-end TIJs like the Anser X1 can create 600 x 600 DPI codes up to 2” tall with stitched printheads.

TIJ printers are often designed for slower speed lines and intermittent coding tasks, but some TIJ models offer high-speed capabilities as well. InkJet, Inc. carries numerous TIJ printers of varying specialties and price points. Our current options include:

See the chart below for a closer look into how our TIJ options compare to one another:

Durable, Permanent Ink for Printing on PVC Plastic

When it comes to PVC pipe coding, using "good enough" ink is anything but. You must achieve high-contrast codes that are easy to read and can stand up to the challenges of the production environment and the wear and tear of long-term use. You need high-quality industrial ink.

We recommend OEM-compatible industrial ink for CIJ printers. These quality alternatives are:

- Cost-effective

- Efficient

- Guaranteed compatible

- Quick and easy to change

- Perfect for high-contrast printing

-

Available in a variety of colors

Our experts will also be happy to work with you to create a custom ink, should you require a more specialized solution for your business's particular needs.

Cutting-Edge Solutions for Coding and Marking PVC

Illegible marks, melting ink, and printer breakdowns become a thing of the past with the right PVC pipe marking and coding solutions. Our experts here at Inkjet, Inc. are happy to help you find exactly the right printer and ink combination for your plant to ensure smooth operations—and crystal-clear codes—for years to come.

Illegible marks, melting ink, and printer breakdowns become a thing of the past with the right PVC pipe marking and coding solutions. Our experts here at Inkjet, Inc. are happy to help you find exactly the right printer and ink combination for your plant to ensure smooth operations—and crystal-clear codes—for years to come.

Inkjet, Inc. is a leading-edge inkjet printer distributor and high-quality ink manufacturer. We pride ourselves on our ability to provide swift, effective solutions to any PVC pipe marking and coding challenges you may be facing—including the need for a custom ink creation. Contact us or call us today at 1-(800) 280-3245 to learn more.