Tetra Pak Printing | InkJet Inc.

Tetra Pak aseptic packaging solutions are used by brands in the food and beverage industry to house thousands of products per day. To achieve this level of output, businesses commonly rely on industrial production lines that move at hundreds of meters per minute. For peak performance and to avoid costly downtime, companies must use line hardware that is capable of reliable performance day in and day out. This is especially true when it comes to industrial printing.

Companies are required by both supply chain guidelines and federal regulations to place traceable codes and markings on their products. Examples include:

- Lot codes

- Serial numbers

- Expiration dates

- Barcodes/data matrices

- Batch numbers

-

QR codes

If these codes are missing, poorly placed, or contain incorrect information, companies may need to perform costly recalls, pay penalties, risk bad publicity, and/or sour supply chain relationships. Fortunately, industrial Tetra Pak printing isn't difficult when you have the expert help of InkJet, Inc.

By offering an array of quality printers and diverse ink options, InkJet, Inc. can help your company ensure traceable markings are placed properly and consistently.

Marking Solutions for Tetra Pak Printing

When it comes to printing on Tetra Pak, companies can choose from a variety of equipment to complete their coding applications. The best hardware choice will depend largely on an operation’s individual needs.

InkJet, Inc. carries multiple printer models and laser systems to meet different Tetra Pak coding and marking needs. Our systems offer industrial outer protections, fast coding speeds, consistent accuracy, and intuitive controls. Moreover, we maintain a robust ink catalog filled with specialty inks that are ideal for specific conditions and applications.

This table lists our various Tetra Pak printing systems and their general specifications. Additional information on each machine can be located further below. Click the title in the table’s leftmost column to jump to a specific solution.

Continuous Inkjet Printers: DuraCode Touchscreen, Keyboard, and Pigment

Continuous inkjet (CIJ) printers are non-contact production line printing systems designed to mark substrates moving at 300 m/min and above. CIJ printers can operate up to 24 hours daily with zero downtime because they’re built with powerful ink circulation systems. The speed, wide ink compatibility, and versatile printheads of CIJ printers enable users to mark thousands of products daily with long-lasting, highly legible codes.

InkJet, Inc. meets diverse coding needs by maintaining a comprehensive CIJ ink catalog with dozens of formulas compatible with Tetra Pak substrates. We have over 30 years of experience producing ink and carry numerous formulations for particular properties, including:

- Superior substrate adhesion

- Heat resistance

- Alcohol resistance

- Rub resistance

- Ultra-quick dry times

- Anti-transfer properties

- Extreme temperature resistance

- Soft and hard pigmentation

- Oil/grease penetation

-

Condensation penetration

InkJet, Inc.’s superior product selection includes printer & ink options to suit your production environment, output demands, and substrate challenges.

|

All DuraCode systems can mark porous and non-porous substrates at speeds up to 320 m/min. Equipped with an IP55 outer structure and able to operate in temperatures ranging from 41-113° F, the DuraCode CIJ can withstand potentially hazardous environmental elements to deliver consistently excellent results. The DuraCode Keyboard and Touchscreen offer the same specifications and compatibility with ink formulas. The only difference between them is their input medium. The DuraCode Pigment has identical specifications as the DuraCode Keyboard and Touchscreen but uses pigmented ink instead of dye ink. |

|

|

See the chart below for a closer look at the DuraCode models’ most important specifications.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

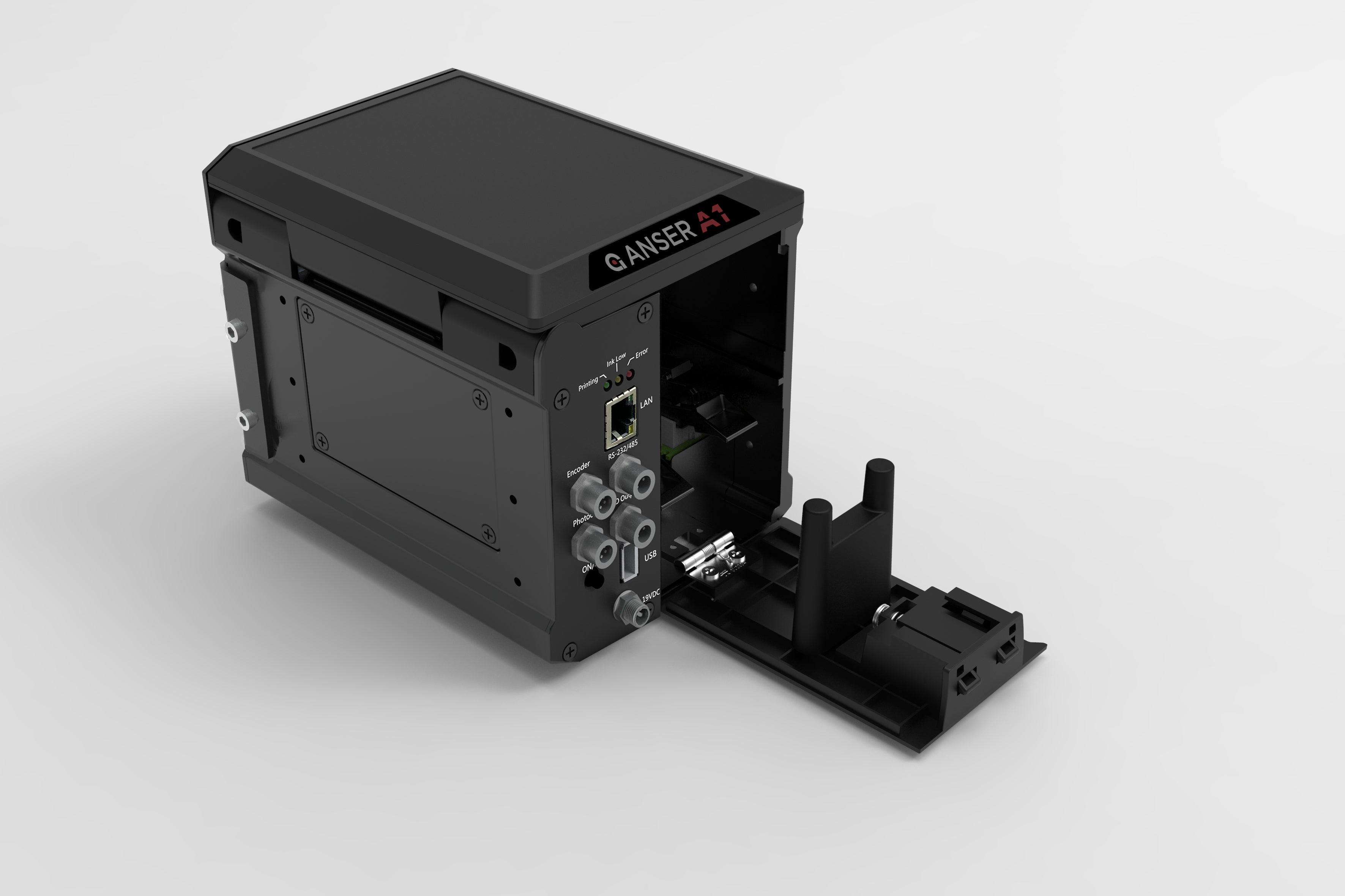

Thermal Inkjet Printers: Anser U2, X1, and A1 Models

Thermal inkjet (TIJ) printers are smaller, lighter, and more cost-effective than CIJ systems. While CIJ systems typically weigh around 100 lbs and cost around $10,000, most TIJ models weigh only 5-10 lbs, with prices starting around $1,499.00.

Although thermal inkjet systems are compact and lightweight, they offer impressive coding specifications. For example, the Anser U2 Smart can create 400 x 300 DPI codes up to 0.5” tall (1” tall with the Anser U2 SmartOne). Higher-end TIJs like the Anser X1 can create 600 x 600 DPI codes up to 2” tall with stitched printheads.

TIJ printers are often designed for slower speed lines and intermittent coding tasks, but some TIJ models also offer high-speed capabilities. InkJet, Inc. carries numerous plastic-compatible TIJ printers with varying specialties and price points. Our current options include:

See the chart below for a closer look into how our TIJ options compare to one another:

Find the Best Ink for Tetra Pak Printing

Regardless of whether you’re using a continuous inkjet printer or a thermal inkjet printer, you won't be able to successfully mark your materials without the right ink. Fortunately, InkJet, Inc. offers a diverse ink portfolio full of unique formulas, including those compatible with Tetra Pak substrates.

At InkJet, Inc., we have been developing ink formulas for over 30 years. From this experience, we have acquired the necessary knowledge to provide companies with the best formulas to fit their needs. Furthermore, if you have distinct substrate requirements that go beyond what standard formulas can deliver, we offer custom ink services to meet every specification. We can customize formula offerings to accommodate your precise requirements, including, but not limited to:

- High-temperature resistance

- Alcohol resistance

- UV readability

- Thermochromic properties (i.e., color changes after the retort cycle)

- Different color varieties

Need Help With Tetra Pak Printing? InkJet, Inc. Is Here to Support You

Tetra Pak aseptic packaging is a great asset in many food and beverage applications. However, it can be difficult to find the right combination of hardware and ink formula to successfully print on this material with precision and consistency. Fortunately, InkJet, Inc. has the printers, ink, and expertise necessary to provide you with the best equipment to fit your Tetra Pak printing needs. Call us today to learn how we can help improve your operation.

InkJet, Inc. is a printer, distributor, and ink manufacturer with years of experience providing top-quality solutions for inkjet printing. For more information related to Tetra Pak printing, contact us online today or call 1(800) 280-3245.