Flat Label Applicator: Best Flat Box Labeler

Cardboard is used by countless companies to house and protect products throughout the distribution process. Whether you use cardboard for primary, secondary, or tertiary applications, you must have well-established variable data marking and product coding workflows. Depending on your industry, type of products, and other factors, you may need to outfit your cardboard packaging with the following information:

- Product title/description

- Barcodes

- QR codes

- Batch numbers/lot codes

- Expiration dates/best-before dates

- Manufacturing date

-

Storage temperature

- Country of origin

- Net weight

- Regulatory symbols

- Company logos

-

Contact information

For large-scale companies, these codes and markings are often applied with the help of industrial equipment and large production lines. But the technologies involved are generally too expensive and large for smaller-scale companies to utilize.

Fortunately, there are more accessible options available today—one of the most popular alternatives is the flat box labeling machine. Here, we take a look at how smaller-size companies can use flat box labeling lines to begin automating their packaging processes and bring case coding applications in-house.

Flat Label Applicator/Flat Box Labeler Options

Like other forms of case coding, flat box labelers streamline secondary packaging marking and minimize physical labeling needs. By using a flat box labeling machine to create pre-printed boxes, companies can:

- Eliminate the need for third-party case coding

- Reduce physical label requirements

- Streamline production by automating the labeling process

-

Set up a solid foundation for further production line scaling

When selecting a flat box labeling machine, companies generally choose from one of two drop-on-demand inkjet printing technologies:

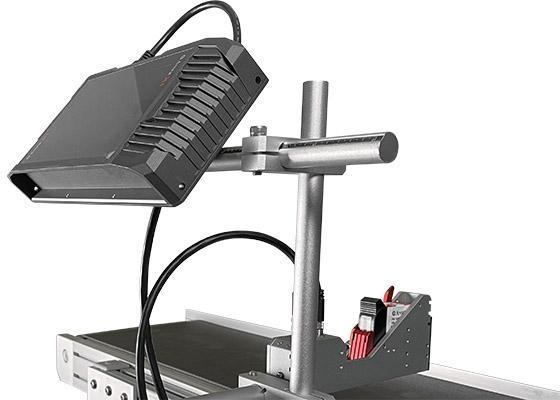

High-resolution case coders like the Precision Series 72mm are production line machines that specialize in creating large graphics, text, and machine-scannable codes. Built with piezoelectric printheads, case coders can utilize thicker inks than other inkjet printers to create more durable, higher resolution codes. Due to these abilities, high-resolution case coders are one of the most popular options for marking cardboard packaging.

On the other hand, thermal inkjet printers are smaller in size than high-resolution case coders but are still able to pack a punch. Despite their compact design, TIJ models like the U2 SmartOne can create high-resolution markings at levels up to 400 x 300 DPI.

In addition, they also frequently offer higher printing speeds than case coders. For example, the SmartOne maxes out at a printing speed of 76.2 m/min while the Precision Series maxes out at 60 m/min. Finally, their relatively low prices make them an accessible option for companies that are just entering the industrial printing field.

High-Resolution Case Coders: Precision Series 18mm & 72mm

High-resolution case coders (hi-res) excel at placing high-quality images and codes on cardboard packaging. InkJet, Inc.’s Precision Series 18mm and Precision Series 72mm are ideal for secondary and tertiary packaging tasks.

High-resolution case coders use powerful piezoelectric printheads to create large messages, intricate graphics, and stark images. Hi-res ink is oil-based and thicker than CIJ or TIJ ink, making hi-res codes more durable and visually appealing. These case coders are well-suited to achieve barcode scannability and contrast at the most economic ink price. As case coding solutions, Precision Series systems enable users to replace physical shipping labels with printed codes, text, and images.

Direct printing holds numerous benefits over manual labeling, including:

- Faster coding times

- Fewer material costs

- Lower risk of coding errors

- Better code durability

-

Improved print quality

In addition to these factors, Precision Series case coders further benefit users with these unique features:

- Internal Barcode Generation: Precision Series case coders can operate as completely standalone machines. Equipped with label design software and internal memory, Precision Series case coders allow users to create and store designs without an external computer.

- Seamless System Integration: Precision Series case coders are compatible with NiceLabel and Windows systems, enabling easy integration with external networks.

-

Dual-Head Functionality: Precision Series printers can be equipped with two printheads, allowing operators to print on two box sides simultaneously, whether for repeat images or independent codes. Users can stack heads to increase image size as well.

See the chart below for a closer look into the Precision Series’ most important specifications:

Thermal Inkjet Printers: Anser U2, A1, and X1 Models

Thermal inkjet (TIJ) printers are smaller, lighter, and more cost-effective than CIJ systems. While CIJ systems typically weigh around 100 lbs and can cost around $10,000, most TIJ models weigh 5-10 lbs and cost as low as $1,499.00.

Although thermal inkjet systems are compact and lightweight, they offer impressive coding specifications. For example, the Anser U2 Smart can create 400 x 300 DPI codes up to 0.5” tall (1” tall with the Anser U2 SmartOne). Higher-end TIJs like the Anser X1 can create 600 x 600 DPI codes up to 2” tall with stitched printheads.

TIJ printers are often designed for slower speed lines and intermittent coding tasks, but some TIJ models also offer high-speed capabilities. InkJet, Inc. carries numerous flat-box-compatible TIJ printers of varying specialties and price points. Our current options include:

See the chart below for a closer look into how our TIJ options compare to one another:

Searching for a Flat Box Labeler for Your Business? InkJet, Inc. Is Here To Help

Tired of using outside services and physical labels to achieve code compliance? Bring case coding in-house with the aid of a flat box labeling machine. By insourcing the case coding process, you can reduce your operation’s physical label needs and streamline the coding process for higher overall efficiency.

Of course, insourcing flat box labeling requires the right combination of hardware, ink, and set-up. At InkJet, Inc., we have all three. Staffed by a team of diverse professionals with experiences in many areas of packaging, InkJet, Inc. has been helping companies of all sizes and backgrounds achieve code compliance for over 30 years. Contact us today to learn how we can help your business.

To find the best flat box labeling machine for your operation, contact us online today or call 1(800) 280-3245.