Thermal Transfer vs Direct Thermal Printing Methods | InkJet, Inc.

Automatic labeling machines use one of two printing methods: thermal transfer or direct thermal. Thermal transfer printing uses a ribbon containing ink or resin that is transferred onto the label through heat and pressure, resulting in durable and long-lasting prints. Direct thermal printing relies on heat-sensitive paper that darkens when exposed to heat, eliminating the need for ribbons or ink. The choice of thermal transfer vs direct thermal printing technologies depends on your specific labeling needs, durability requirements, and intended use of the printed material. The table below provides a quick comparison of the two methods.

Thermal Transfer vs Direct Thermal Printing: InkJet, Inc. Has The Solutions to Meet Your Needs

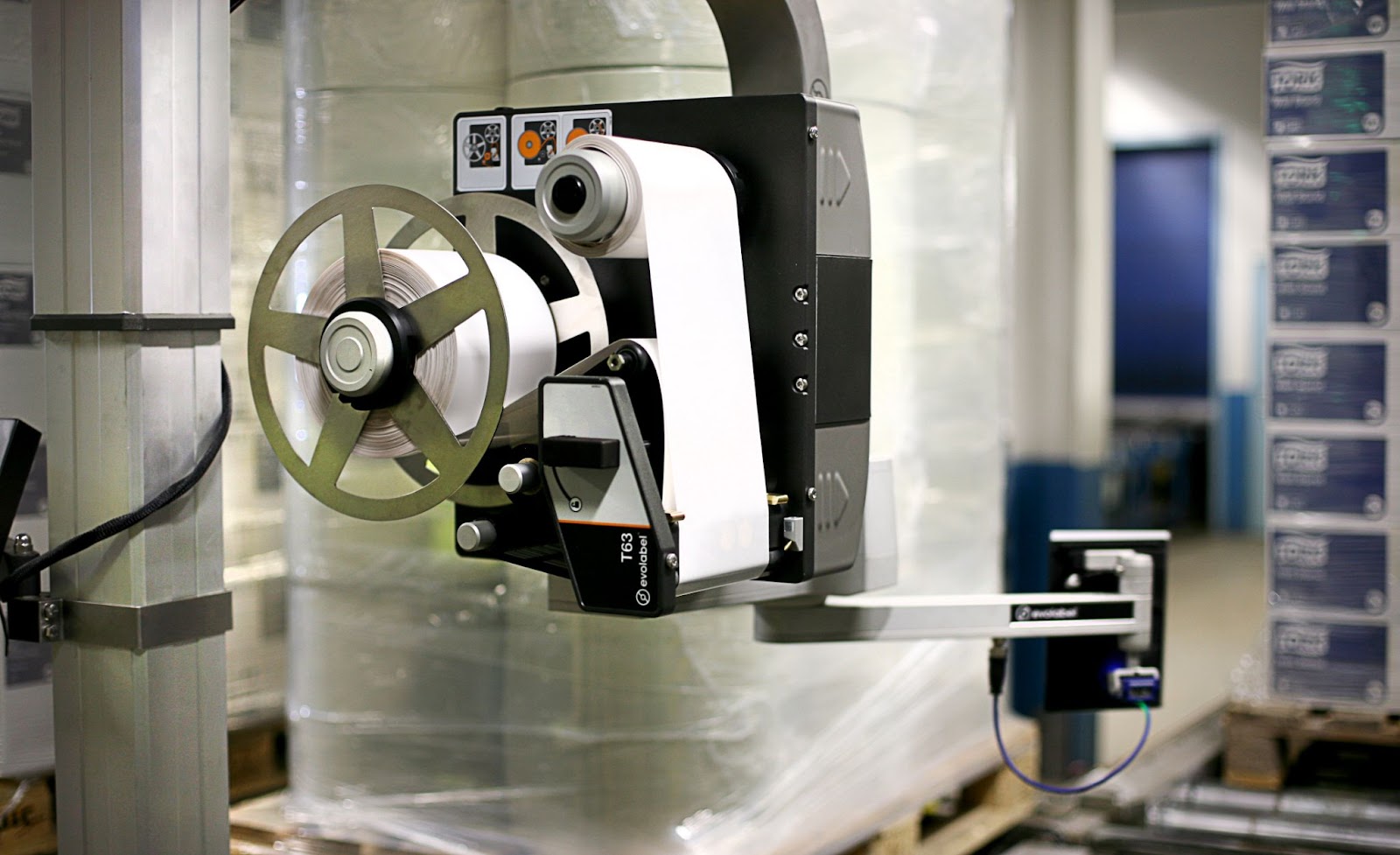

InkJet, Inc. offers EvoLabel print-and-apply labeling machines (PALM) that streamline the labeling process by continuously creating and applying labels to products or shipping cartons. PALM systems include both thermal transfer and direct thermal printing methods.

Two of the most essential components of the EvoLabel PALM systems are:

- The printer module, which prints labels on-demand

-

The label applicator, which dispenses and applies each label to a product, carton, or pallet

By selecting the ideal printer/applicator combo, you can use a PALM system to label your products quickly, accurately, and efficiently.

By employing an Evolabel system, you can simplify your case package labeling process, reduce the risk of error, and maximize packaging efficiency.

InkJet, Inc. Simplifies the Selection Process

Choosing the right labeling machine depends on the materials you're coding, the unique qualities of your products, and your cost and sustainability goals. You need a labeler to handle your products' surface quality and fit into your production line. Let InkJet, Inc.'s experts help determine which labeling machine is suitable for you.

To learn more about the different types of automatic labeling machines and which will most benefit your operation while meeting your sustainability requirements, contact InkJet, Inc. today by dialing (800) 280-3245.